2002 TORNINOVA AIR BASIC 1.250

2002 TORNINOVA AIR BASIC 1.250

Contact us for price

Description

AIR BASIC BUBBLE FORMING MACHINE

lamiantor for LDPE rolls

various bubble sizes for technical packaging and reflective insulation.

Constructor's description:

A thermoforming process laminates two individual films using a special heating bar to blow hot-air over the films.

Compared to traditional off-line systems, this process significantly reduces energy consumption and provides maximum production planning flexibility with its "stop-on-phase" procedure. Such special features serve to significantly reduce

inventory, transportation and energy costs.

Because the AIR BASIC system is so versatile and easy to use, a single, unskilled operator can quickly

perform production changeovers without wasting material when restarting. The on-board network connection

allows remote monitoring of machine functioning via Internet and the system’s modular configuration lends

itself to many useful upgrades such as a 3rd layer lamination unit, perforation unit, etc. The AIR BASIC

series is still one of the most purchased lines for the production of air bubble film for technical packaging and

reflective insulation.

UNWINDING UNIT with two position unwinding (one for each layer) complete of air expansion-shafts

(internal Ø. of the core 76 mm.), belt-brakes and lateral adjustment devices. Designed for the unwinding of

rolls of LDPE, coated paper, aluminium, etc..

CENTRAL UNIT complete of independent motorized nip-rolls in order to set the tension for each film,

banana rolls, calenders heated by water into closed circuit for the pre-heating of the films, forming cylinder

with bubbles diameter 10 mm. and 4 mm height complete of quick joint for water and suction,

thermoforming by special hot air oven in steel heated by electrical resistances with electrical movement on

rack controlled by touch screen, silicon rubber cylinder for material welding, vacuum pump for sectional

aspiration on the forming cylinder through auto lubricating flange. This kind of thermoforming system allows

the stop-on-phase of the machine (without breakage of the films).

THERMOREGULATION WATER UNIT BRAND COREMA to control and to maintain

constant the temperature of the forming cylinder and of the pre-heating cylinders.

THIRD LAYER LAMINATION UNIT to laminate a third layer of film over the bubble complete of

welding cylinder; film heating by special hot air oven in steel heated by electrical resistances.

LONGITUDINAL BLADES to split the roll of air-bubble film in different parts, complete of blade

holders in aluminium and hard steel blades, pneumatic driving gear controlled from the touch screen.

FORTH LAYER UNWINDER to laminate a 4th layer film (HDPE film, PE-foam, coated aluminum

foil or kraft paper, printed film, non-woven, etc.) to the base of the air bubble film, improving or varying the

finished film’s aesthetic and/or mechanical characteristics. It consists of a double-station unwinder equipped

with two air expansion shafts for loading the 4th layer film rolls. While a roll is unwinding on one station, a

new roll can be prepared in stand-by on the other for a no-stop changeover. This modular unit is easily

retrofitted to any new or existing in-line air bubble film machine.

SEMI-AUTOMATIC WINDING UNIT Contact model on rubber cylinder of Ø 200mm, cutting

system to the measure inserted on the control panel through blade working on rodless a cylinder, air

expansion shafts store with manual loading system, automatic reel change, 2 air expansion-shafts. Sound

signal to advice the operator of the phase of change and for missed presence of shafts on the store. Regulator

for the rewinding tension. Push-button panel on board group for independent control of the rewinder. The

winding is with internal bubbles or third layer

PNEUMATIC, ELECTRONIC AND HYDRAULIC CONNECTIONS between the various

parts of the plant.

MAIN CABINET on closet complete of motor inverters, PLC, fuses, contact breakers and all the

different protections. Digital display device with touch-screen for insertions parameters, selections and

settings of the plant functioning.

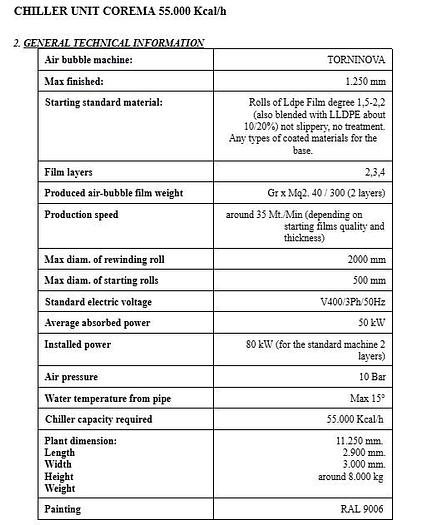

CHILLER UNIT COREMA 55.000 Kcal/h

Specifications

| Manufacturer | TORNINOVA |

| Model | AIR BASIC 1.250 |

| Year | 2002 |

| Condition | Used |

| Stock Number | GEEK100 |