BARMAG AIR TEXTURIZING LINES

BARMAG AIR TEXTURIZING LINES

Contact us for price

Description

BARMAG AIR TEXTURIZING LINES for the production of artificial grass yarn

The supply can be split as follows:

- Texturizing machine

- Barmag twister with 36 spindles.

- SIMA Winder with 4 groups of 15 heads each

- Roblon T5000 n.4 units

- SIMA T2TR n.3 units

- Fare Extruder

- Meromat rope making machine for the production of 4-strand ropes up to 16 mm.

- 1 monofilament extruder FARE

These machines are used to texturize synthetic grass.

less than 500 worked hours, as new

" texturizers available, each one consists of:

monofilament texturizing unit for one yarn, with 2 electrically heated godets, each one with separating roller

diameter: 132mm - length: 150mm

1 heating zone per godet

godet temperature: maximum 180 °c

temperature tolerance on godet surface: +/- 2 °c

temperature tolerance between godets: +/- 1.5 °c

separating rollers with ball bearings, with 1 piece texturing jet

for texturizing of various yarns

heater for compressed air with automatic temperature and pressure control

cooling drum with blower and air filter

diameter of cooling drum where the textured yarn is running: 346mm

blower capacity: 2.2 kw

large size air filter

chromium plated take-off roller with separating roller to supply the textured yarn from the cooling drum to the winder

precision winding with electronic gear for changing the winding ratio several times

during winding of one bobbin for excellent bobbin quality even with the slippery artificial grass monofilament

fully automatic bobbin change

with magazine for up to 4 pieces of empty winding tubes

winder with decreasing bail roll pressure and with decreasing winding tension for

winding of textured yarn with excellent bobbin quality

winding on to cheap paper tubes typically used in bcf yarn production

bobbin dimensions:

inner diameter: 73mm

length of tube: 290mm =/- 0.5mm

traverse: 250mm

outer diameter of tube: 79mm

deposit of finished bobbin on to parking position below the winder

signal flash lamp for alarm of empty tube magazine

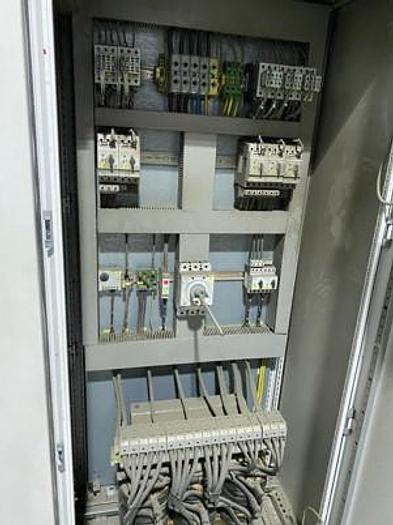

switch control box with number of inverters for each texturing position

1 inverter for each unrolling position, total 2 pieces

1 inverter for each heated godet, total 2 pieces

1 inverter for cooling drum, 1 piece

1 inverter for take-off roller, 1 piece

4 inverters for automatic winder, total 4 pieces

total number of inverters per position, total 10 pieces

make of inverters: siemens

each 2 positions consist of the following units:

1 unrolling tower with 2 unrolling positions, each unrolling position is yarn tension

controlled

each unwinding position suitable for following tube dimensions

flanged bobbins with:

tube inner diameter: 90mm

diameter of flanges: 260mm

tube length: 310mm

traverse: 280mm

Specifications

| Manufacturer | BARMAG |

| Year | 2010 |

| Condition | Used |

| Stock Number | GESF100 |